Shredder

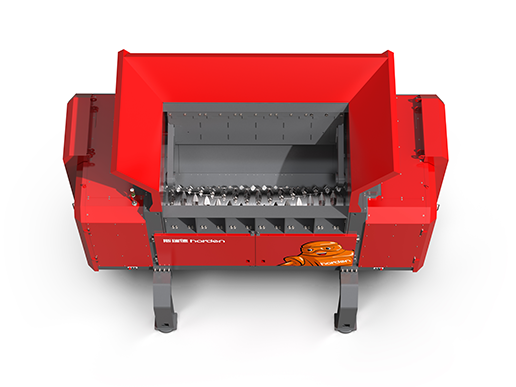

One-Step Shredder (SG 3000MP)

The SG3000MP is an integrated shredder engineered for processing various types of solid waste under complex operating conditions. It features a robust structural design, high-torque output, and an advanced cutting system, ensuring finer, more uniform, and higher-capacity output.

These enhancements improve shredding efficiency while optimizing operational reliability.

What Distinguishes The

One-Step Shredder

What distinguishes

40-130mm

Particle Size

2*200kw

Power Rating

6406*3253*4988(L*W*H)(mm)

Dimensions

What Materials Can Be Shredded?

Shredded materials

Advantages At A Glance

Advantages

Our Case

Our Case

Specific Parameter

-

SG3000MPDimensions(L*W*H)(mm)6406*3253*4988Hopper Opening(mm)2960*950Feeding Height(mm)3375View MoreHopper Capacity(m³)4.8Discharge Width(mm)765Total Weight(kg)35000Shredding Size(mm)40-130Cutting Lengh(mm)3000Shaft Speed(rpm)133Number of Rotating Knives(pcs)75/90Number of Fixed Knives(pcs)12Power Rating(kw)2*200Electric Conrtrol System15Electric Cabinet Dimensions(mm)3000*2200*800Drive ControlVariable Frequency Drive

Download the brochure

One-Step Shredder-SG3000MP.pdf

Perfect Solid Waste Solution

Custom-made solution

For special requirements, we offer the custom-made solution!

Recommendations

Recommendations