The combi vibrating screen organically combines the two single screening technologies of the flip-flow screen and the ladder screeninto one, so that one piece of equipment can achieve two screening effects at the same time.

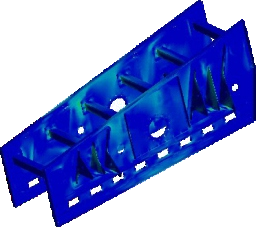

Based on the principle of mechanical vibration, this equipment uses a single excitation source to provide excitation force, andsimultaneously drives the upper and lower screening plates to produce different forms of vibration.

The upper screening plate is incircular vibration, and the lower screening plate is in relaxation motion. Under the action of the vibration projection of the machine, stratification and transportation are realized. Materials smaller than the mesh size fall down and complete the particle size classification

What Distinguishes

The Combi Screen

What Materials Can Be Separated?

Advantages At A Glance

Our Case

Specific Parameter

-

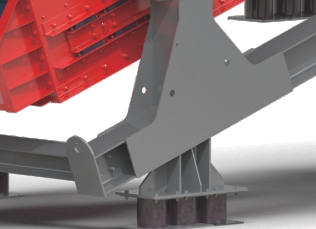

SZS-C1660Drive Power (kw)45Capacity (m³/h)60-80Screening Area (mm)1600*6000View MoreMachine Dimension (mm)7200*4000*6200Machine Weight (t)15