Separator

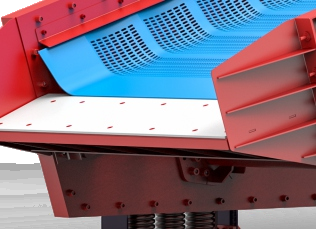

Flip-Flow Vibrating Screen

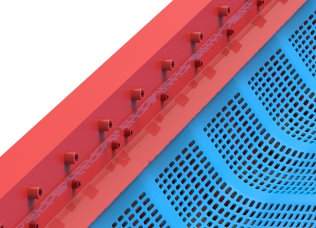

According to the principle of mechanical vibration, a single drive is used to generate dual vibrations, so that the dynamic screen plateobtains extremely high acceleration through tension and relaxation deformation.

lt is suitable for difficult-to-screen materialsespecially materials with high wet viscosity that are prone to clogging and jamming. , the flexible screen plate and relaxation effecihave very powerful screening efficiency and anti-blocking performance.

What Distinguishes

Flip-flow Screen

What distinguishes

20-25m³/h

Maximum Throughput Capacity

22kw

Dirve Power

1600*5200mm

Screening Area

What Materials Can Be Separated?

Separated materials

Advantages At A Glance

Advantages

Our Case

Our Case

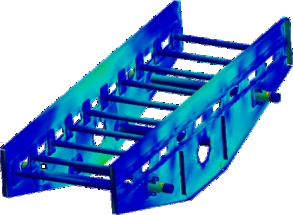

Specific Parameter

-

VF2060Screening Area (mm)2000*6000Screening Size (mm)10-50Drive Power (kW)30View MoreWeight (kg)8700Throughput (m³/h)28-35Dimensions (L*W*H)(mm)7298*3997*3354

Download the brochure

SIZE SCREEN.pdf

Perfect Solid Waste Solution

Custom-made solution

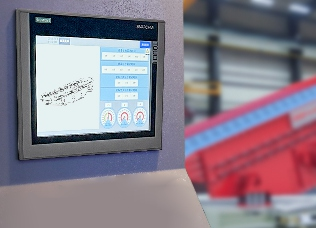

For special requirements, we offer the custom-made solution!

Recommendations

Recommendations