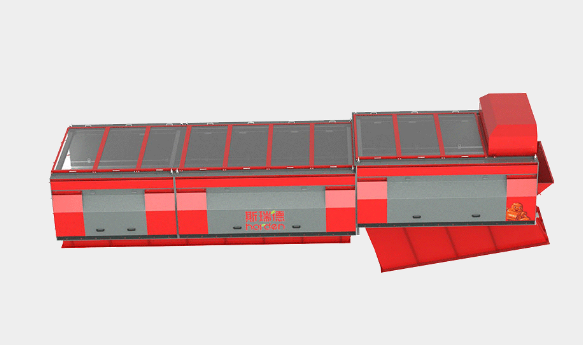

Separator

Hexagon Disc Screen

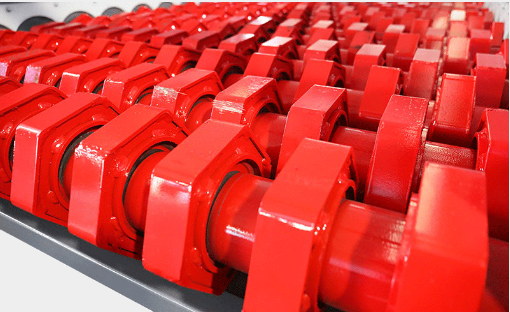

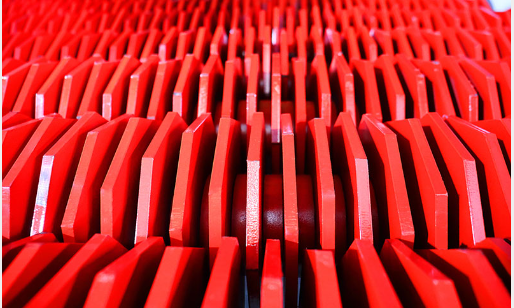

HARDEN disc screen is a screening equipment that rolls and separates materials of different sizes and shapes through polygonal discs. All the polygonal discs rotate in the same direction with the rollers, causing the materials on the polygonal discs to achieve a compound movement of horizontality and tumbling, making the materials looser.

The materials are hit, spread, and perform jumping and tumbling motions by the rotating polygonal discs. During the process, the particle size smaller than the gap between the discs will be missed from the gaps on the side of the polygonal disc, thereby realizing the screening function.

What Distinguishes

The Disc Screen

What distinguishes

15-20t/h

Maximum Throughput Capacity

7.5kw

Power

20-350mm

Screen Hole Size

What Materials Can Be Separated?

Separated materials

Advantages At A Glance

Advantages

Our Case

Our Case

Specific Parameter

-

HDS2000Working Width (mm)1600Woring Length (mm)2000Power (kW)7.5View MoreScreening Size (mm)10-350Weight (kg)3600Dimensions (L*W*H)(mm)1962*2323*1277

-

HDS3000Working Width (mm)1600Woring Length (mm)3000Power (kW)7.5View MoreScreening Size (mm)10-350Weight (kg)4800Dimensions (L*W*H)(mm)2931*2323*1277

Download the brochure

SIZE SCREEN.pdf

Perfect Solid Waste Solution

Custom-made solution

For special requirements, we offer the custom-made solution!

Recommendations

Recommendations