Shredder

Single-Shaft Shredder-SL Series

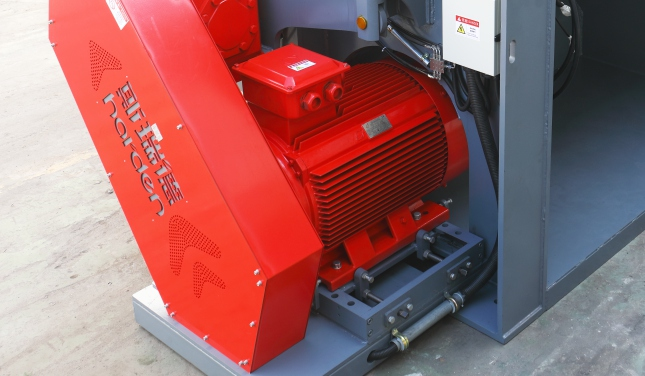

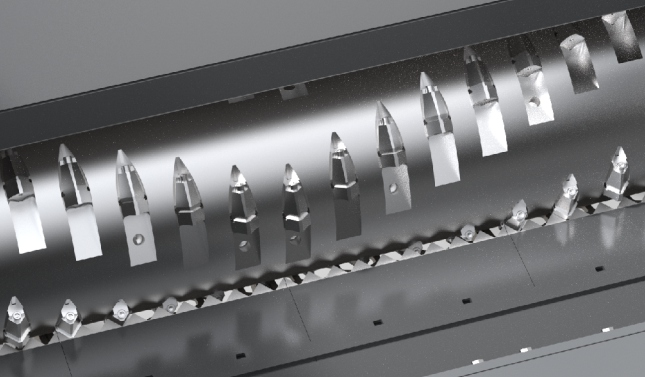

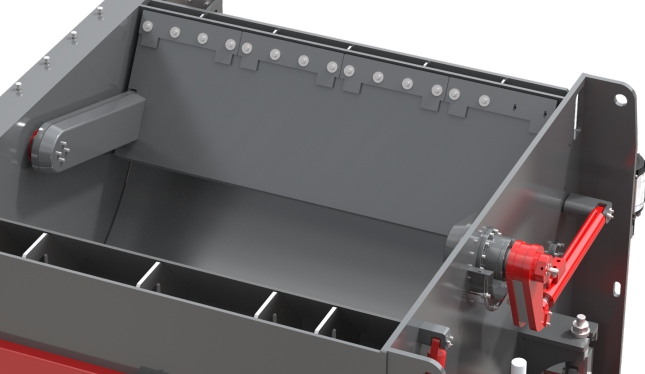

HARDEN SL series shredder is a stationary shredder specially developed for the solid waste treatment industry. This eguipment is suitable for a wide range of materials, has powerful features, and is highly intelligent.

Its powerful torqueand shearing force can easily handle various solid waste materials such as hard plastics, plastic films, polyester textiles and large-ton bags. In addition, the power system of this equipment is strong and reliable, and it is suitable for primanshredding or one-step shredding processes of various solid waste materials.

What Distinguishes The

SL Series Single Shaft Shredder

What distinguishes

3-5t/h

Maximum Throughput Capacity

40-130mm

Particle Size

90-160kw

Driving Power

What Materials Can Be Shredded?

Shredded materials

Advantages At A Glance

Advantages

Our Case

Our Case

Specific Parameter

Specific Parameter

-

SL1500Dimensions (L*W*H)(mm)3300*3220*4740Total Weight (kg)14500Cutting Length (mm)1500View MoreRotor Speed (rpm)82Cutting System TypePNumber of Rotor Knives (pcs)54/81Number of Counter Knives (pcs)3Number of Screens (pcs)3Power(kW)110Hydraulic Power (kW)7.5Dirve ControlFrequency Converter

-

SL2000Dimensions (L*W*H)(mm)3800*3220*4740Total Weight (kg)16500Cutting Length (mm)2000View MoreRotor Speed (rpm)82Cutting System TypePNumber of Rotor Knives (pcs)72/108Number of Counter Knives (pcs)4Number of Screens (pcs)4Power(kW)132Hydraulic Power (kW)7.5Dirve ControlFrequency Converter

-

SL2500Dimensions (L*W*H)(mm)4300*3220*4740Total Weight (kg)19000Cutting Length (mm)2500View MoreRotor Speed (rpm)82Cutting System TypePNumber of Rotor Knives (pcs)90/135Number of Counter Knives (pcs)5Number of Screens (pcs)5Power (kW)160Hydraulic Power (kW)7.5Dirve ControlFrequency Converter

Download the brochure

SINGLE-SHAFT SHREDDER.pdf

Perfect Solid Waste Solution

Custom-made solution

For special requirements, we offer the custom-made solution!

Recommendations

Recommendations