Shredder

TP Series Electric Primary Shredder

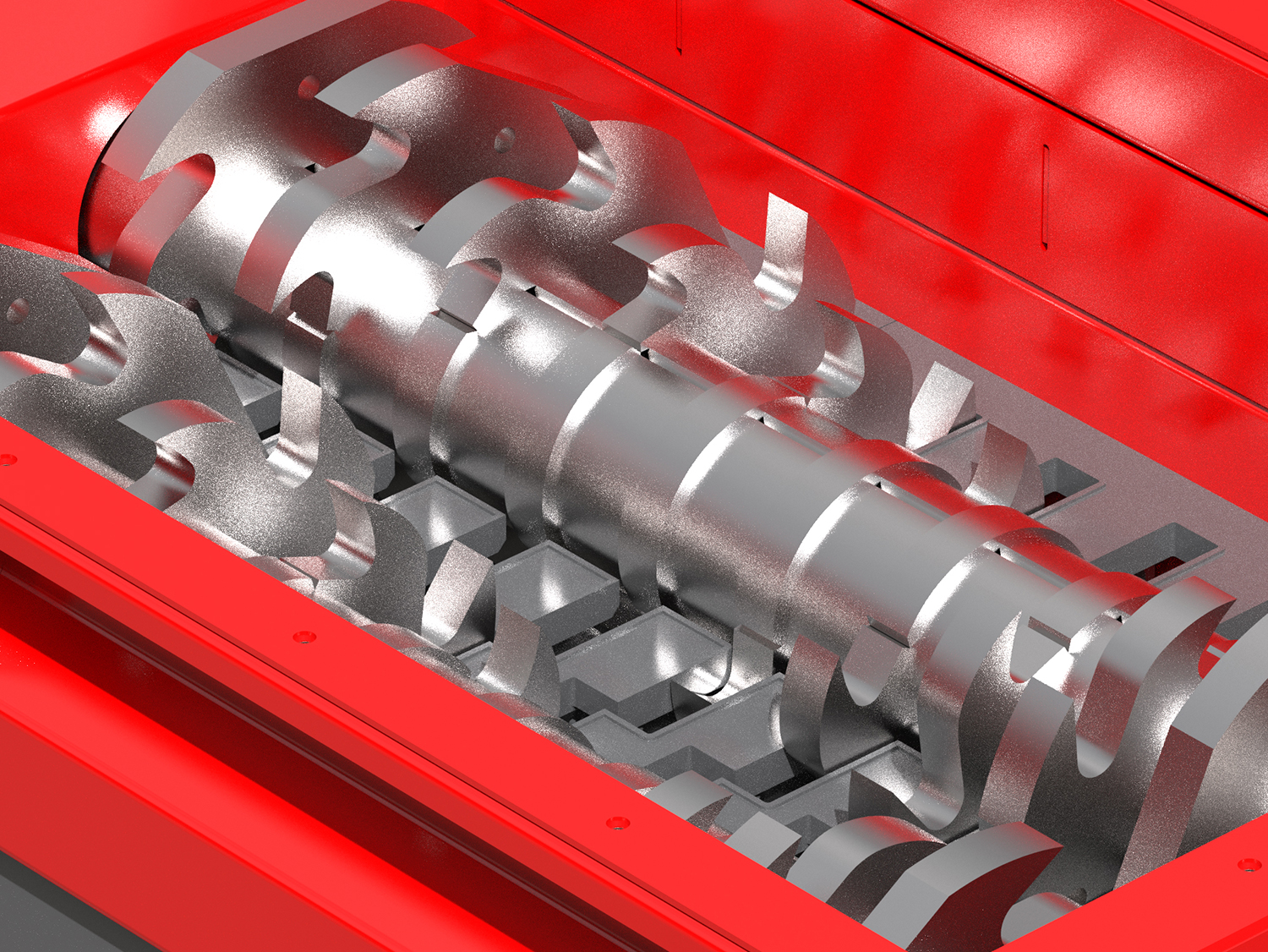

The Harden TP Series Electric Primary Shredder is engineered for high-capacity primary size reduction in large-scale

waste processing systems.

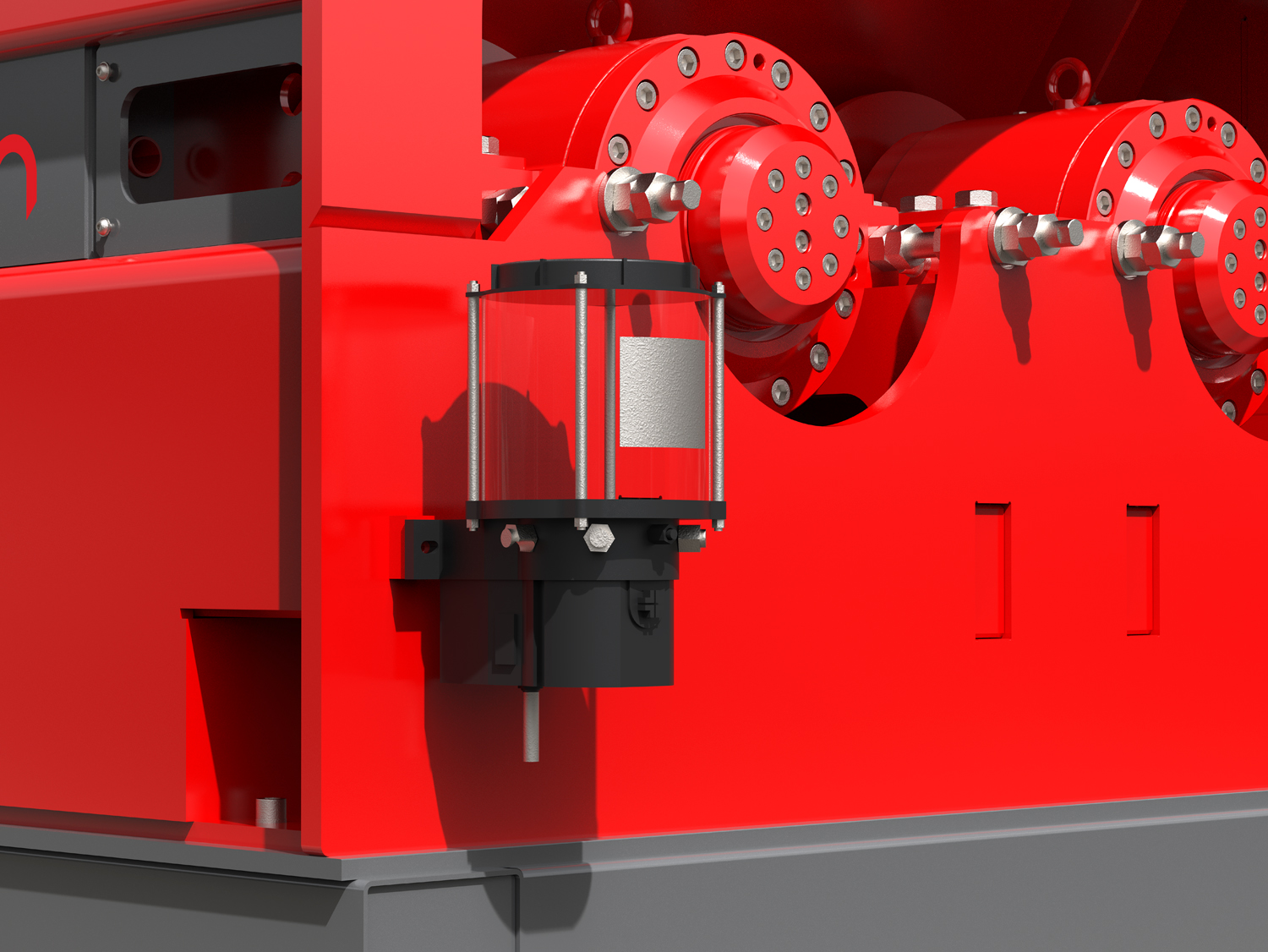

Featuring a heavy-duty mechanical structure, energy-efficient operation, and a maintenance-friendly design, it delivers

stable performance with a low total operating cost.

As a reliable front-end shredding solution, the TP Series is well suited for a wide range of solid waste and recycling

applications, supporting efficient downstream processing.

What Distinguishes the

TP Series Electric Primary Shredder

What distinguishes

30-100t/h

Throughput Capacity

80-400mm

Output Size

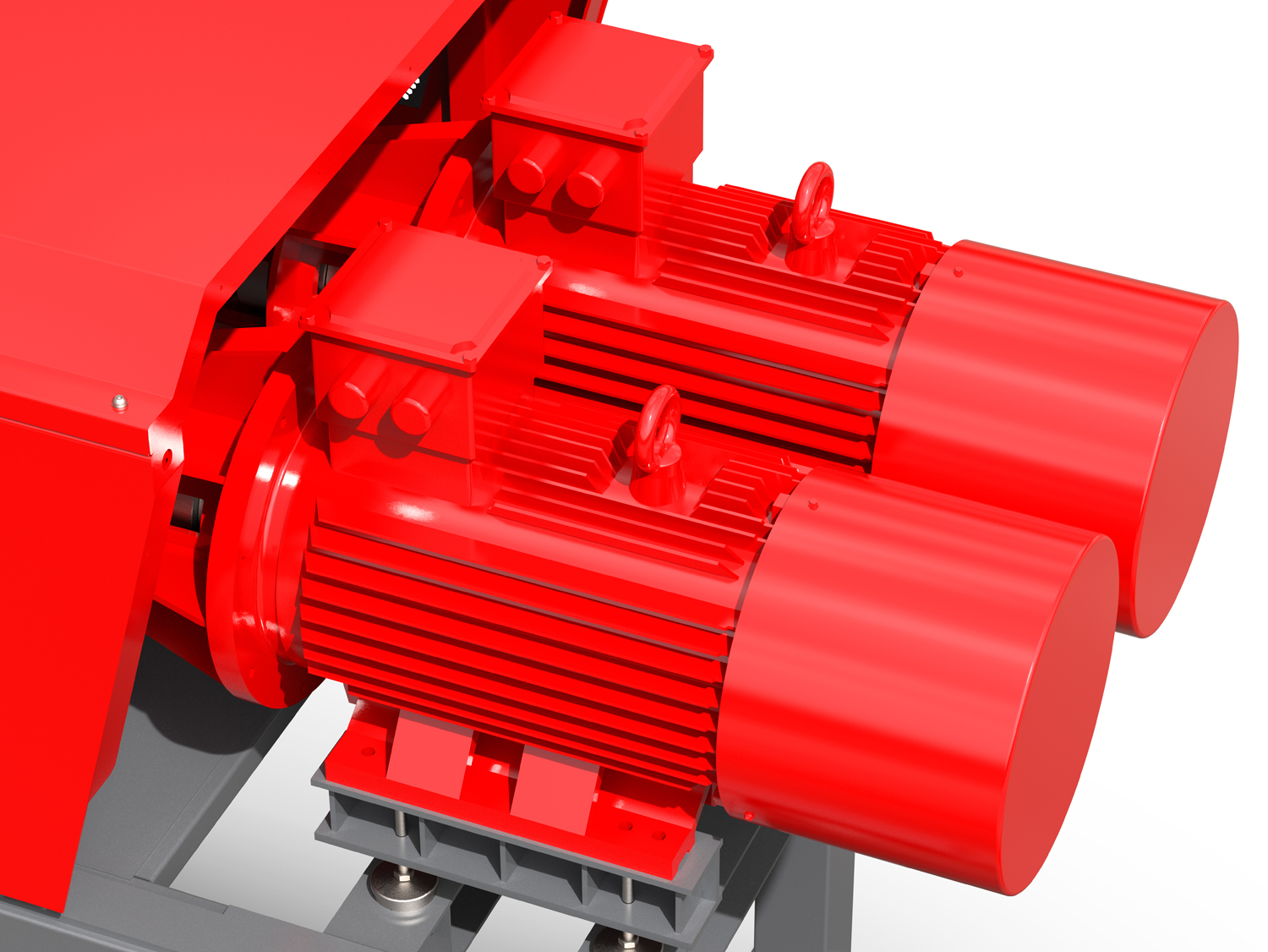

2*160/2*200kW

Power

What Materials Can Be Processed?

Applicable Materials

Advantages at a Glance

Advantages

Specific Parameters

-

Technical SpecificationsModelTP1826Equipment DimensionsDimensions (L*W*H) mm7000*2338*1400View MoreTotal Weight kg27000Cutting ChamberDimensions (L*W) mm2700x1900Rotor Speed rpm54Rotor Knife Thickness mm80Number of Rotor Knives pcs20/22Drive SystemDriveElectricPower kW2*160/2*200Electrical Control SystemDrive ControlFrequency Converter

Download the brochure

TWO-SHAFT SHREDDER.pdf

Perfect Solid Waste Solution

Custom-made solution

For special requirements, we offer the custom-made solution!

Recommendations

Recommendations