Mastering RDF for Cement Kilns: Harden's Game-Changing Solution

As the cement industry pivots toward sustainability, Refuse-Derived Fuel (RDF) has emerged as a promising alternative to fossil fuels.

Yet, many cement plants struggle with RDF's challenges: inconsistent combustion, high impurities, or low substitution rates that fail to deliver efficiency.

The secret to unlocking RDF's potential? A tailored, high-quality RDF preparation system that meets the precise demands of cement kilns. Harden Machinery's collaboration with a leading Chinese cement plant showcases how this works, transforming industrial waste into a reliable, high-value fuel.

Cement kilns demand precision—high temperatures (around 900°C), stability, and continuous operation. For RDF to succeed, it must meet three critical requirements:

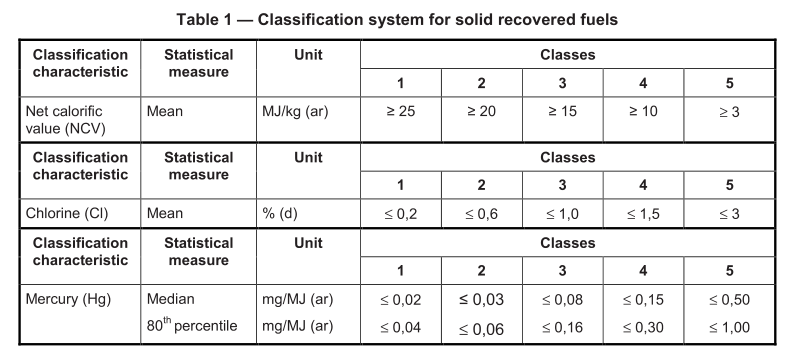

● Stable Calorific Value: RDF must deliver consistent heat (3500–5500 kcal/kg, depending on kiln type) to avoid temperature fluctuations that could compromise clinker quality or increase coal use.

● Low Impurities: High ash (>40 wt%), sulfur (>2 wt%), or chlorine (>1.5–2 wt%) content can clog preheaters, corrode equipment, or degrade clinker strength. Strict impurity limits are essential, as outlined in industry standards (e.g., T/CIC 049-2021).

● Uniform Particle Size: RDF particles sized 30–50 mm ensure stable feeding and efficient combustion, preventing blockages or unburned residues in the kiln.

Rather than settling for off-the-shelf solutions, the cement plant partnered with Harden Machinery to build a bespoke RDF preparation system, designed from the ground up to meet these exacting standards.

From Waste to Fuel: A Precision Process

Harden's RDF preparation system turns mixed industrial waste into high-quality fuel through a streamlined, intelligent process:

1. Strategic Raw Material Selection

The cement plant leverages abundant local industrial waste—textiles, plastics, and other combustibles comprising over 85% of the mix.

With a base calorific value of 3800–5500 kcal/kg, these materials require no additional combustible agents. Sourced from nearby industrial parks (hundreds of tonnes daily), the waste stream ensures a steady supply with fewer impurities than municipal solid waste (MSW), setting the stage for high-quality RDF.

2. Advanced RDF Preparation System

Harden's DWS RDF preparation system, customized for the plant’s waste profile, combines fine shredding, magnetic separation, and air classification to deliver uniform, high-purity RDF:

● Fine Shredding: Dual-stage shredding with adjustable speeds and wear-resistant alloy blades tackles tough materials like textiles, preventing wrapping and ensuring consistent 50 mm particles. This boosts calorific stability by 30%.

● Precise Screening: Magnetic separators remove metals, while windshifters separate lightweight combustibles from heavy inerts, achieving a 95% impurity removal rate for stable kiln combustion.

● Intelligent Design: Anti-clogging screens and durable components reduce maintenance downtime, ensuring reliable output tailored to the kiln's needs.

3. Seamless Operational Integration

To match the plant's 5000 t/d clinker line, which consumes 900 tonnes of fuel daily, Harden’s system delivers 20 t/h of RDF—enough for a 20% coal substitution rate (300 t/d). Optimized for total cost of ownership (TCO), the system minimizes blade replacement costs, enhancing long-term efficiency.

Real Results, Real Impact

The plant's leadership shared their experience: “Harden’s RDF system has transformed our operations. It’s not just about meeting carbon reduction goals—it’s a smart way to cut coal costs and tackle waste challenges. High-quality RDF is now a cornerstone of our sustainable production.”

By addressing kiln-specific needs, Harden's system delivers:

● Higher Substitution Rates: Stable, high-calorific RDF boosts TSR without compromising kiln performance.

● Reduced Emissions: Low-impurity RDF minimizes environmental impact.

● Cost Savings: Replacing 20% of coal lowers fuel expenses significantly.

The Harden Advantage

Harden's approach goes beyond equipment—it's about crafting solutions that align with each client's unique waste stream and operational goals. This project proves that high-quality RDF isn't a trend; it's a transformative fuel for cement plants aiming for sustainability and profitability.

Ready to turn your waste into a powerful resource? Explore Harden Machinery’s RDF preparation systems and discover how our shredders, screens, and windshifters can drive your green transition. Visit our website for tailored solutions.