Harden Machinery Supports Sustainability Through Waste-to-Energy Technologies

Harden Machinery Ltd., a leading Chinese manufacturer of solid waste equipment, is promoting sustainability through innovative waste-to-energy technologies and custom solutions for solid waste management. The company aims to address critical waste challenges and support the cement industry’s decarbonization efforts by developing refuse-derived fuel (RDF) preparation systems that reduce carbon emissions and enhance resource efficiency.

Harden Machinery Supports Sustainability Through Waste-to-Energy Technologies

In a world grappling with pressing waste management challenges and an escalating demand for renewable energy, Harden Machinery (“Harden” or the “Company”), a leading solid waste equipment manufacturer in China, has announced its commitment to promoting sustainability through innovative waste-to-energy technologies. By leveraging advanced solid waste treatment technology and robust research and development capabilities, Harden is poised to deliver tailored solutions to meet the diverse needs of global solid waste management.

Potential of the Waste-to-Energy Market

According to the Global Waste to Energy Market Report, the industry is expected to reach a market size of approximately $47 billion by 2025, with a compound annual growth rate of around 5.8%. This growth is largely driven by increasing waste generation, the need for renewable energy resources, and technological advancements alongside substantial government support for waste-to-energy projects.

The waste-to-energy process typically involves generating energy in the form of electricity or heat via the incineration of waste materials. Harden aims to harness this technology to address critical waste management issues while contributing to the production of alternative fuels. With over 14 years in the solid waste treatment sector, the company has focused on developing refuse-derived fuel (RDF) or solid recovered fuel (SRF) preparation systems for municipal waste.

Challenges and Solutions in the Cement Industry's Decarbonization

The cement industry faces significant challenges in global decarbonization efforts. Current data suggests that industrial process emissions during cement clinker production account for about 60%-65% of emissions, primarily due to carbon dioxide released from the decomposition of carbonates. Furthermore, emissions from energy activities constitute approximately 35%-40%, mainly from burning fossil fuels such as coal. Indirect emissions from electricity usage are not included in carbon emissions statistics, making the quest for alternative raw materials to replace limestone and other carbonates particularly daunting.

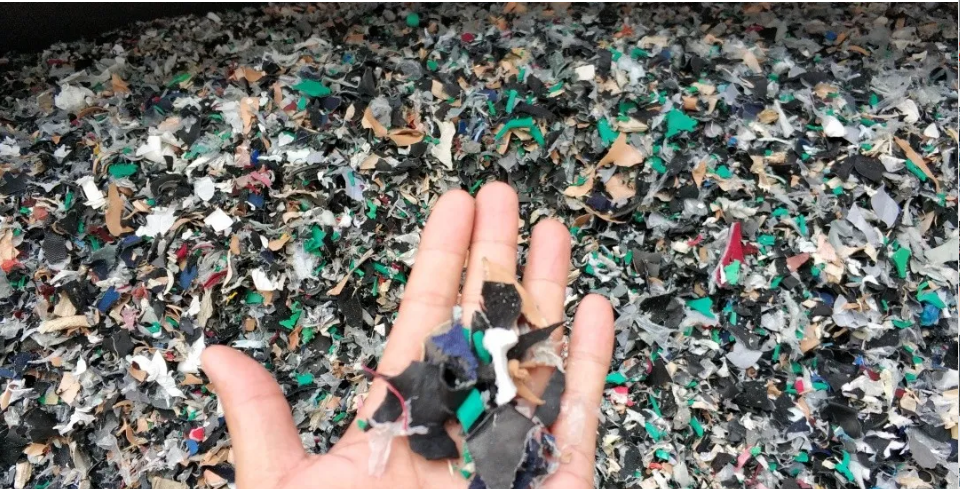

In response to this challenge, Harden has introduced RDF substitute fuel preparation technology. By reducing fossil fuel consumption and increasing the share of clean energy, the use of RDF has emerged as a mainstream method for lowering carbon emissions. Harden has spent years delving into solid waste treatment and has conducted extensive experiments with prevalent RDF raw materials, such as waste fabrics, leather scraps, waste plastics, and light residues from paper mills, continuously improving and optimizing its equipment to meet kiln fuel needs.

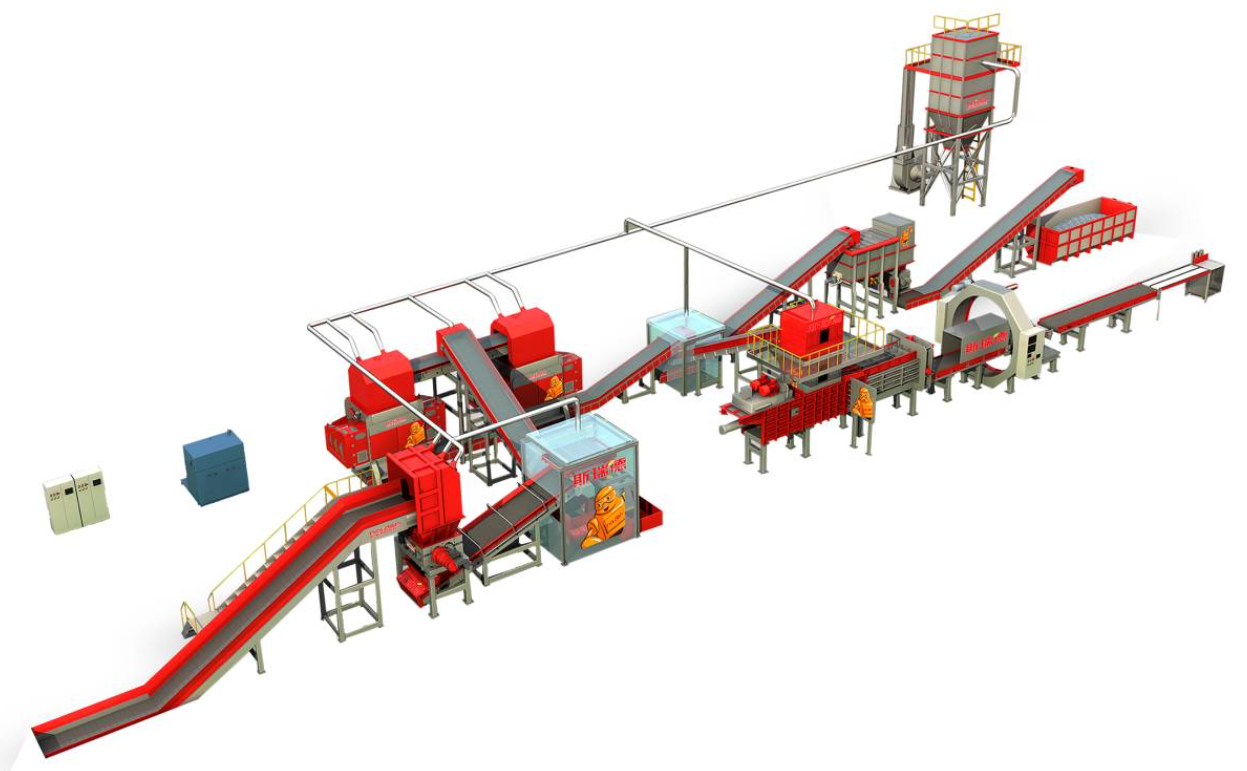

Innovative RDF Substitute Fuel Preparation System

Harden has launched an industrial solid waste RDF preparation system based on the philosophy of "Just Shred it, Thus Sort it," which is compatible with various solid waste types. This system employs advanced industrial preparation techniques such as shredding, magnetic separation, wind speed modulation, sorting, and dust removal, effectively separating combustible materials and impurities from various solid waste. The end product achieves a granule size of approximately 50 mm, with an impurity removal rate exceeding 95%, generating high calorific value RDF substitute fuel.

From a global development perspective, carbon markets can play a decisive role in resource allocation, meaning that cement companies equipped with RDF preparation systems stand to greatly benefit. This approach not only reduces carbon emissions during production processes but also propels the industry toward a more sustainable future.

As Harden advances its commitment to sustainability, we look forward to seeing how innovative technologies will contribute to global waste management and energy transition efforts.

For more details: https://www.hardenshredder.com/industrial-waste-disposal-system.html