Classification Analysis of RDF Shredders

Based on the number of shafts and structural design, HARDEN’ s RDF shredders are primarily categorized into single-shaft, two-shaft, and four-shaft systems, each with distinct technical characteristics and application scenarios.

HARDEN’s single-shaft shredder features a high-speed rotating shaft with dynamic blades working against fixed blades to achieve shearing and tearing.

The output particle size is precisely controlled by a replaceable bottom screen. For example, HARDEN’ s RDF production line employs a hydraulic pusher and spiral blade arrangement to achieve a particle size below 30mm, with a yield rate exceeding 95%.

Key Advantages

Precise particle control: Interchangeable screens allow adjustment between 40-100mm, meeting feed requirements for cement kilns and incinerators.

High-toughness material processing: A high-speed (90 RPM) blade system efficiently shreds plastics, leather scraps, and other resilient materials.

Smart operation: Integrated PLC system monitors torque and screen blockage, enabling automatic parameter adjustment and fault alerts.

Typical Applications

RDF fine processing: Often used as a secondary shredder in RDF production lines to refine pre-shredded materials, improving fuel uniformity and combustion efficiency.

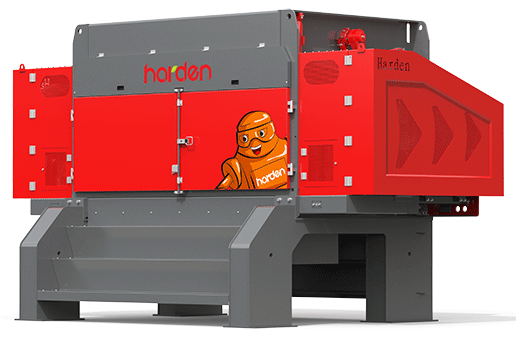

2. Two-Shaft Shredder: The "Primary Workhorse for Mixed Waste"

Two-shaft shredders utilize two counter-rotating shafts with interlocking blades to shear and twist materials, ideal for mixed and contaminated waste.

For instance, HARDEN’ s TD912 model employs high-torque design to process metals, plastics, and other hard/soft mixtures, with output sizes below 150mm.

![]()

Key Advantages

High throughput & adaptability: Low-speed (26 RPM), high-torque operation handles wet, tangled waste like plastic films and textiles.

Superior pre-processing: Serves as a primary shredder for rapid volume reduction before sorting and fine shredding.

Low maintenance: Modular blade design allows individual replacement, minimizing downtime and costs.

Typical Applications

MSW pre-treatment: HARDEN’ s two-shaft shredders process 200+ tons/day in Southeast Asian waste facilities, boosting overall efficiency.

Industrial waste shredding: Leather scraps, fabric waste, etc., are shredded to ~80mm RDF pellets for cement kilns and power plants.

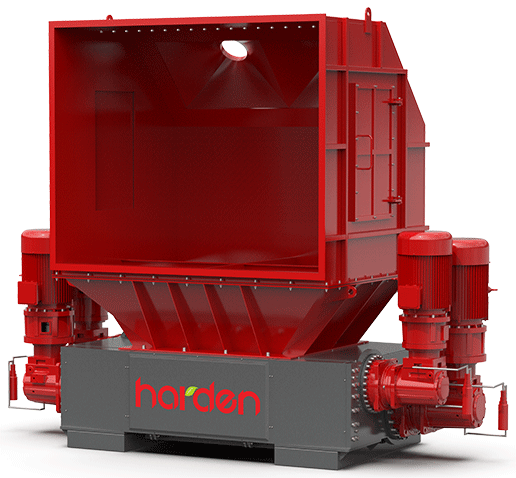

3. Four-Shaft Shredder: The "Versatile Performer for Complex Materials"

Four-shaft shredders employ two pairs of shafts for multi-stage shredding: upper shafts for pre-shredding and feeding, lower shafts for fine shearing and compaction.

Particle size is controlled by blade thickness and screen aperture. HARDEN’ s QSH series features independent smart control, increasing shear frequency by 30%.

Key Advantages

Efficient, uniform output: Four-shaft synergy achieves 20-80mm particles in one pass, ideal for e-waste and contaminated soft materials.

Energy-saving & stable: Hydraulic-electric hybrid drive reduces energy consumption by 20% vs. conventional four-shaft systems.

Smart monitoring: CCTV and big data analytics optimize shaft speed and torque in real time, ensuring stability and fault prevention.

Typical Applications

High-value RDF production: Shreds waste textiles and solid waste to <30mm for premium RDF.

Hazardous waste: Pre-treatment of medical waste, chemical drums, etc.

Bulky waste recycling: Mattresses, sofas, etc., are shredded with metal recovery via magnetic separation.

Selection Guide:

Primary shredding: Two-shaft for mixed waste volume reduction.

Fine shredding: Single-shaft for strict RDF/TDF particle requirements.

Complex materials: four-shaft offers cost efficiency for e-waste and hazardous waste.