An “Economic” Tool for the Resourceful Treatment of Decoration Waste: RDF/SRF Preparation

In the past, the decoration waste was generally left untreated in open temporary piles, or covered with soil after being piled up, or landfilled on the outskirts of town. These methods of disposal will occupy a large amount of land and are very likely to cause serious secondary pollution to the environment.

Decoration Waste Mountain

Leading the decoration waste disposal industry, from “non-hazardous simple landfill” gradually evolved to “resource recycling” is gradually becoming the trend.

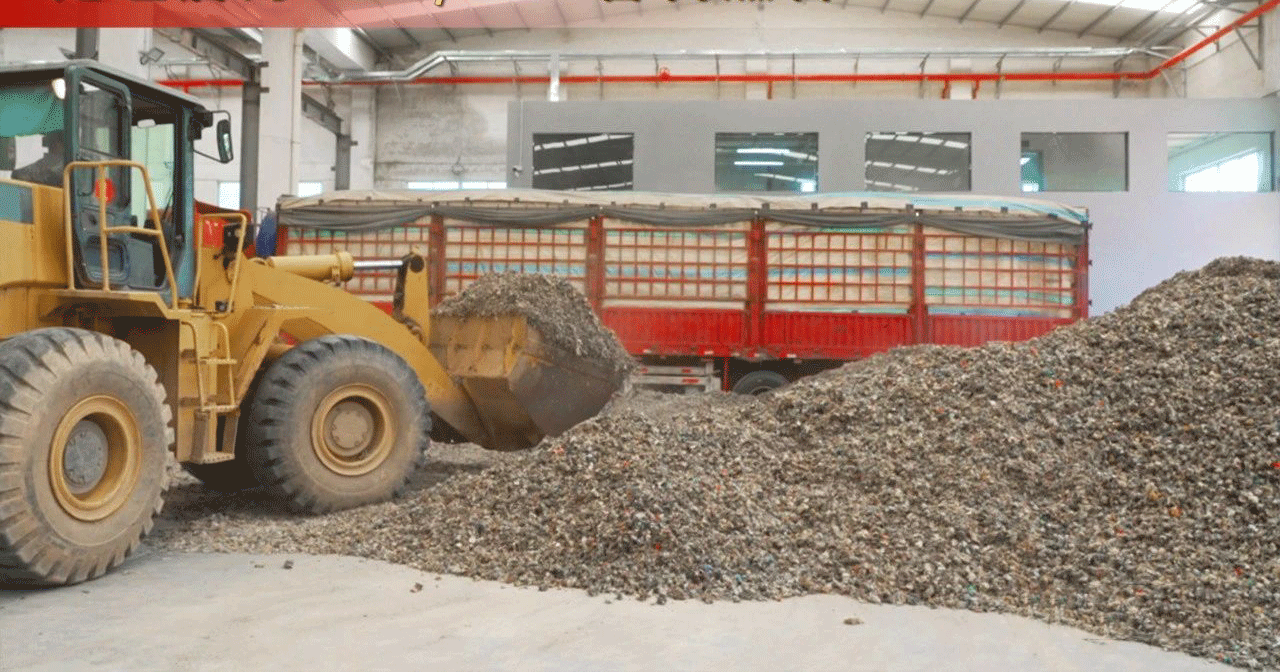

At present ,it mainly focuses on the “gravel and dirt” in decoration waste, recycling it into different sizes of aggregates, often ignoring the high calorific value of the waste that is sorted out, the composition of which is mainly wood, fabrics, paper, plastics and woven bags.

According to the characteristics of these complex wastes, Harden Machinery Ltd. has been deeply cultivating in the solid waste treatment industry for more than ten years, proposes to adopt the treatment concept of “Just Shred It, Thus Sort It”, and reprocess the high calorific value wastes of decoration wastes into RDF/SRF alternative fuels.

Decoration Waste Before Disposal

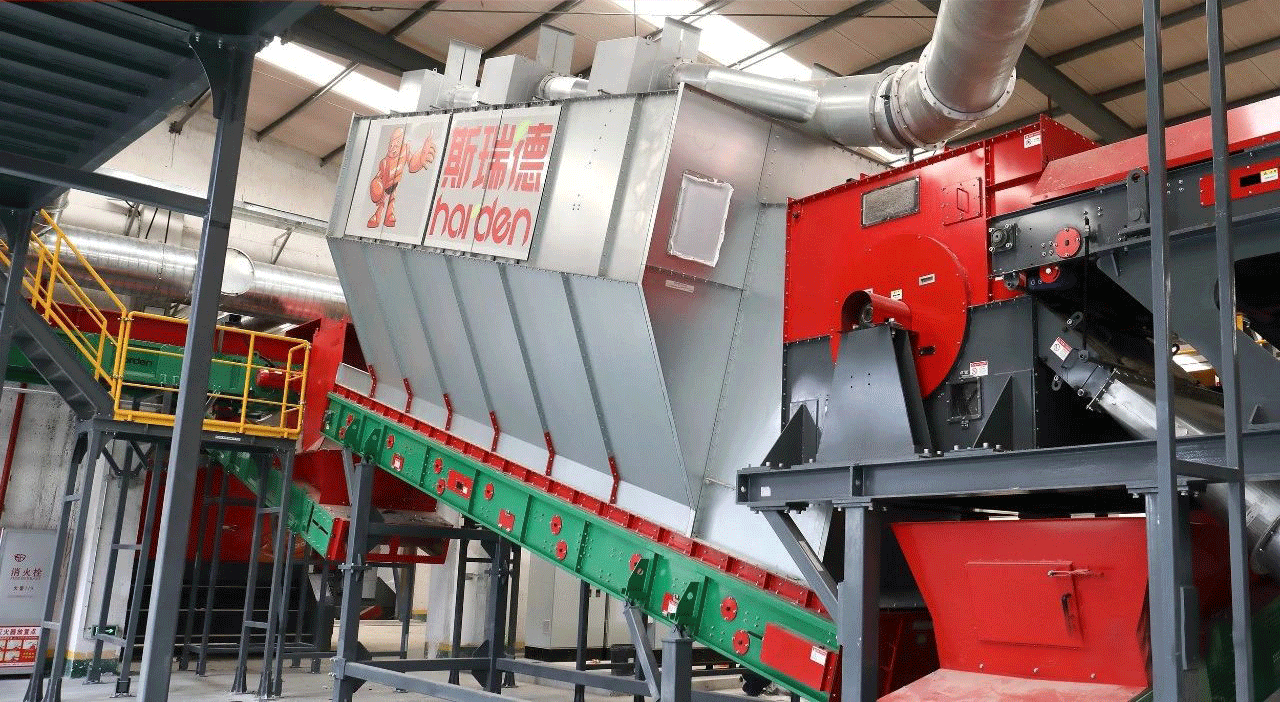

Decoration Waste RDF/SRF Preparation System

This system performs multiple screening processes before preparing alternative fuels to separate metals, heavy substances, dust, gravel and other components, making the final RDF/SRF alternative fuel purer, with higher calorific value and better economic benefits for sale.

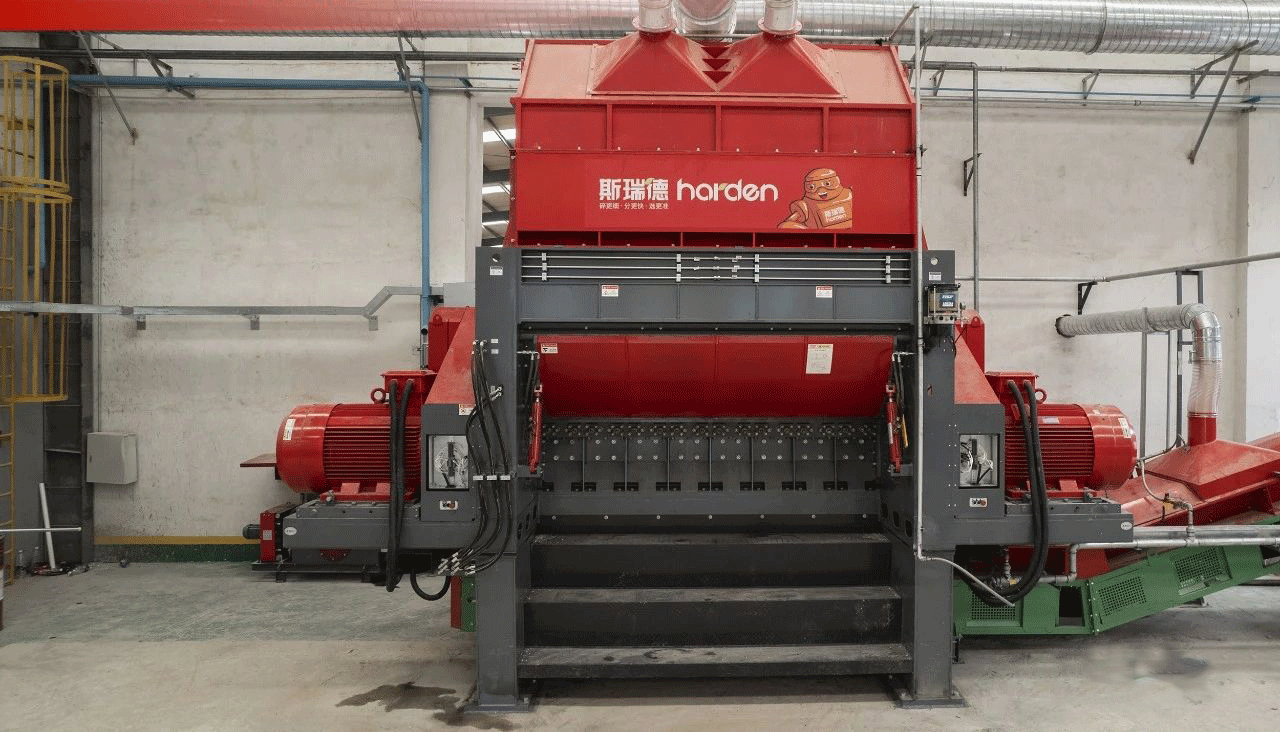

Single-shaft Shredder

Wind Shifter

Double-shaft Shredder

Disc Screen

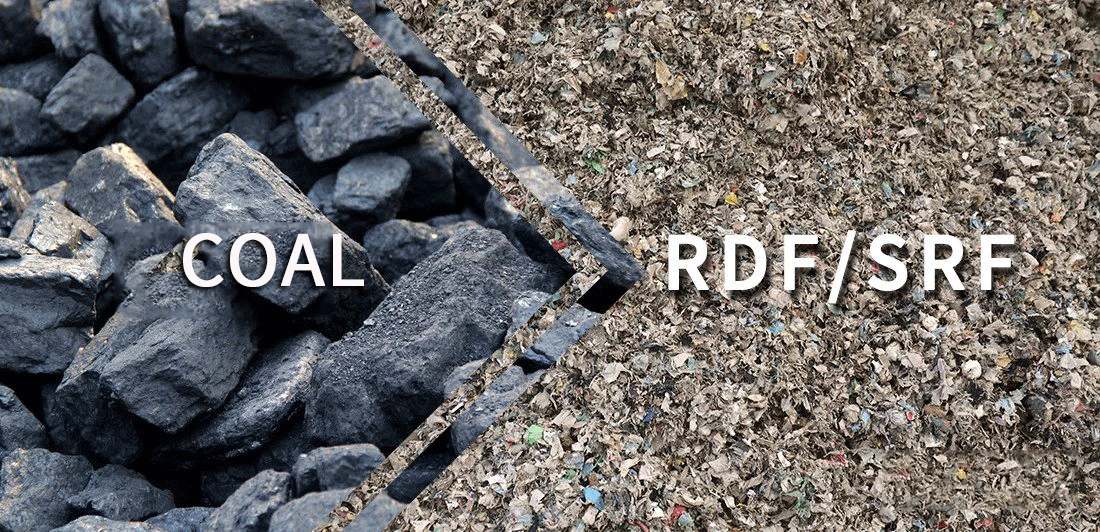

Application of RDF/SRF

These RDF/SRF prepared from decoration waste are mainly sold in power plants, cement plants and other industrial kilns to replace traditional fuels (e.g., coal, etc.), with an average of every 1.4 tons of alternative fuels equal to about 1 ton of standard coal, a heat substitution rate of about 68%, but at one-third of the cost price of standard coal, and with only one-quarter of the CO₂ emissions of coal.

SRF/RDF

It is an “economic” solution for the resource treatment of decoration wastes under the background of critical environmental issues.

The system, with multiple screening processes prior to the preparation of alternative fuels, separates out metals, heavy materials, ash, gravel and other components, resulting in a purer, higher calorific value, and more economically viable sale of the final RDF/SRF alternative fuel.

In the historical context of economic green transformation, the effective ways of limiting carbon emissions is inevitably to explore the possibility of energy-saving transformation in process production on the basis of scientific production limitation.

The use of RDF/SRF alternative fuels to replace traditional fossil fuels is the most effective measure to achieve carbon reduction in the cement industry at this stage.

Therefore, the preparation of RDF/SRF from high calorific value wastes is a highly innovative cross-cutting application and an effective solution to expand the economic returns from the resource-based treatment of renovation waste.