Why did a cement company deploy more than a dozen RDF alternative fuel preparation projects?

On the one hand, as the popularity of infrastructure construction recedes and the real estate market continues to cool down, a large number of excess cement products are backlogged in warehouses.

Market competition has become increasingly fierce, prices have been continuously depressed, corporate profit margins have been severely squeezed, and survival pressure has increased sharply.

On the other hand, the cost of cement production is even worse. The price of raw materials has been rising, and energy costs such as coal and electricity have also remained high.

Coupled with the tightening of environmental protection policies, energy conservation and carbon reduction are like a more stringent hurdle.

Enterprises need to invest a lot of money in upgrading and upgrading environmental protection equipment to reduce emissions of harmful gases such as carbon dioxide, and actively explore green and low-carbon development paths.

This is undoubtedly a huge challenge for many cement companies that are strapped for funds and have difficulty in technological transformation. While striving to meet environmental protection requirements, they must also take into account economic benefits. It is really a dilemma.

Faced with these difficulties, a domestic cement company conducted detailed market research and analysis and found a solution to the current predicament - RDF alternative fuel. It can replace fossil fuels such as coal and be used in cement kilns, thereby achieving the dual effects of reducing energy costs and reducing carbon emissions.

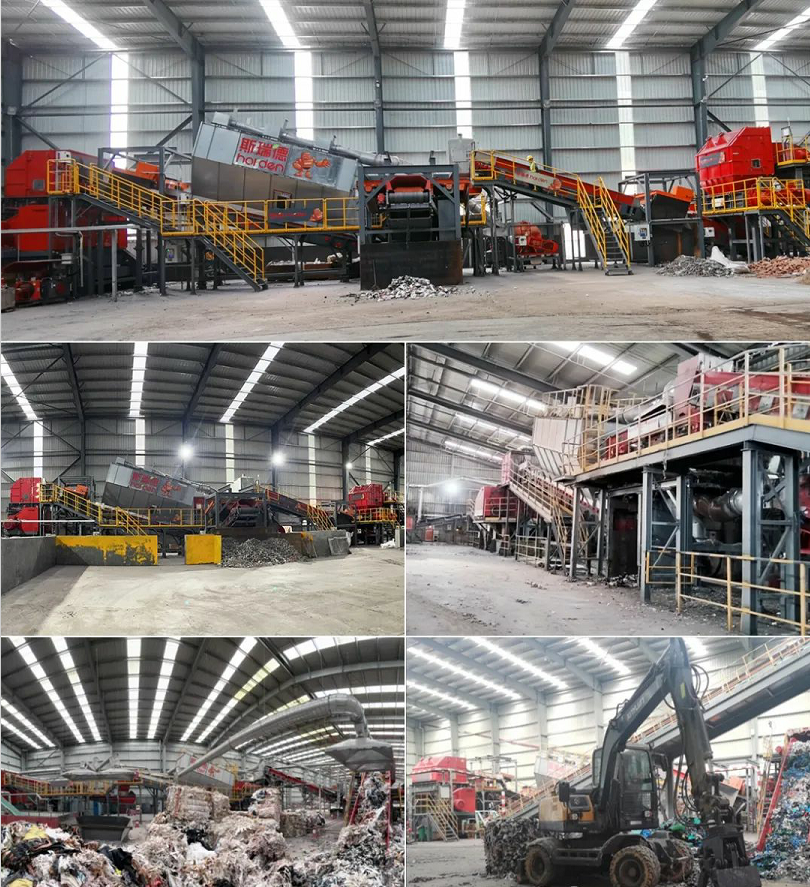

As a result, the cement company will start building RDF alternative fuel preparation centers in multiple regions from 2021. Up to now, there are more than a dozen RDF alternative fuel preparation projects completed or planned.

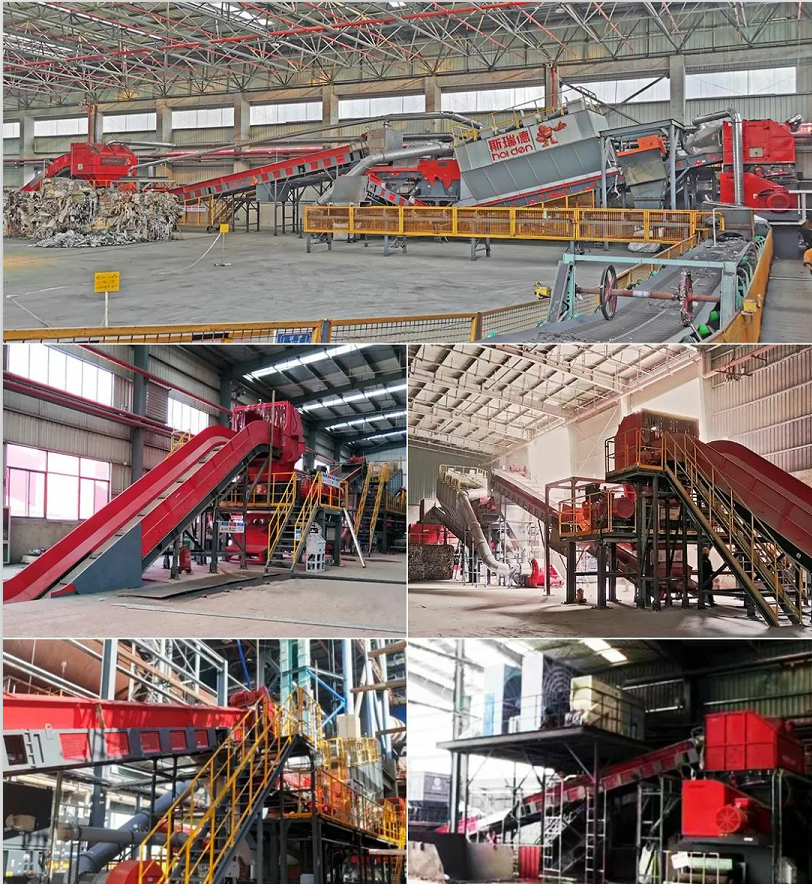

Harden Machinery’s RDF alternative fuel preparation system they use is not only suitable for a variety of solid waste materials, such as textile waste, industrial solid waste, biomass, bulky waste, decoration waste, etc.

The overall design focusing on the solid waste treatment concept of "Just shred it, thus sort it.”

The final output material has a higher combustion calorific value, fewer harmful elements, a lower heat loss coefficient for combustion in the kiln, and has a lower impact on cement kiln fluctuations and cement The impact on quality is smaller.

Harden RDF alternative fuel preparation system is an innovative solid waste resource treatment system that can amplify the value of solid waste. It uses "fine crushing + intelligent air separation + powerful magnetic separation" and other automated solid waste treatment processes to separate combustibles and impurities from various types of industrial solid waste, and finally obtain a size of tens of millimeters and an impurity removal rate of Reaching more than 95% of high calorific value RDF alternative fuel.

The cement company said: "We believe that RDF alternative fuel may become one of the commonly used fuels in cement kilns in the future. This is not only a positive response to carbon emission reduction policies, but also an important way to reduce the operating costs of coal-fired enterprises through technological innovation.

The multiple attributes of energy saving, emission reduction, coal saving and cost reduction of RDF alternative fuel are the golden key for cement companies to open the door to green production transformation. "

Harden believes: "The large-scale application of RDF alternative fuels will, on the one hand, turn the industrial solid waste that originally needed to be processed into a valuable resource, reducing the region's daily need for recycling and harmless treatment of industrial waste;

On the other hand, it will On the one hand, it provides cement companies with new fuels that can replace high-carbon emissions and high-cost fossil fuels (coal).”

The cement industry officially entered the carbon trading market, which completely ignited the application of RDF alternative fuel in cement kilns. In the future, as this "flame" burns brightly, cement companies with RDF alternative fuel preparation centers will seize the opportunity and benefit from it.